Home page / Товары / Laser Accessories / FB-LD-RAD-HHL

FB-LD-RAD-HHL

- Specification

- Delivery

- Guarantee

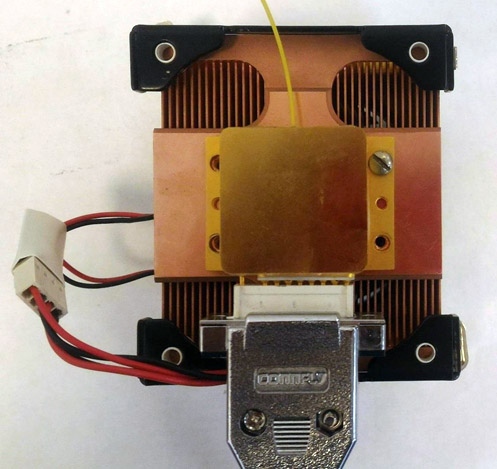

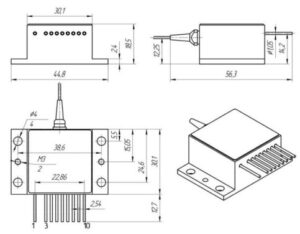

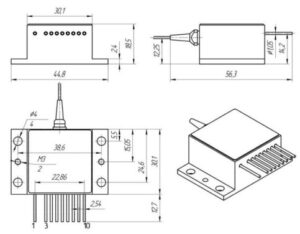

Laser module consists of following parts:

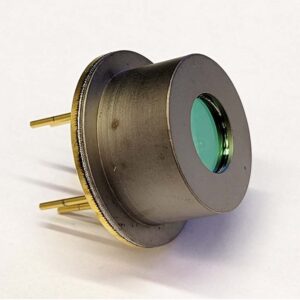

1) Laser diode in HHL package;

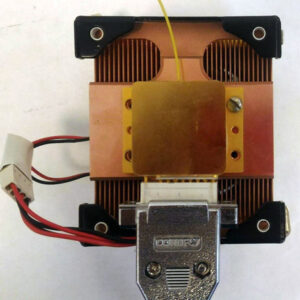

2) Copper radiator with a cooling fan;

3) Connecting cable between the radiator and a pumping driver.

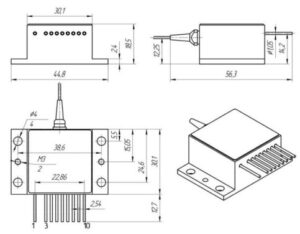

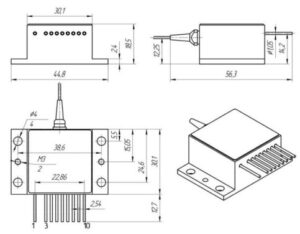

HHL package is a hermetically sealed package with 9 pins. The package contains:

laser diode, Peltie thermocooller, thermoresistor, laser emission input system into optical fiber and other laser design elements.

1-TEC (-)

2

3- NC

4-Laser Anode (+)

5-Thermistor (2)

6-Thermistor (1)

7-Laser Cathode (-)

8- NC

9- NC

10-TEC (+)

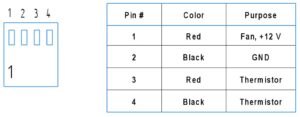

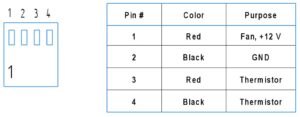

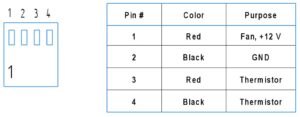

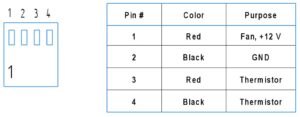

Pinouts assignment of the additional connector HU-4 (4 pins)

1-TEC (-)

2

3- NC

4-Laser Anode (+)

5-Thermistor (2)

6-Thermistor (1)

7-Laser Cathode (-)

8- NC

9- NC

10-TEC (+)

Pinouts assignment of the additional connector HU-4 (4 pins)

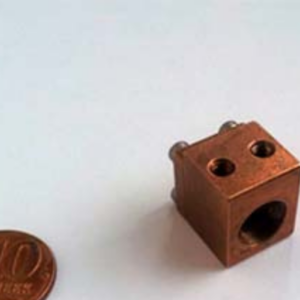

Package mounting and heat sink recommendations.

To guarantee effective laser diode and built-in Peltie thermocooller operation it is necessary to provide sufficient heat sink from the lower surface of HHL package. For this purpose HHL package must be mounted on a radiator using a heat sink paste (thermopaste) like KTP-8 (not included).

Laser module also includes a radiator of copper plates equipped with a fan for compulsory cooling.

To install HHL package onto the radiator surface it is necessary to use mounting holes of the package with M3 screws (included).

Non-compliance of above requirements may result in decrease of output optical power and failure of Peltie thermocooller.

Fiber optic operation recommendations.

Standard optical fiber allows bending radius up to 70-100mm, therefore to avoid its damage it is strictly prohibited to exceed above mentioned fiber bending radius during operation with the laser module, its transportation or storage!

In case of operation of the laser diode with fiber bend exceeding radius allowed following situations are possible:

1) Reversible decrease of optical power to do with failure of optical fiber waveguide behavior when due to strong bending part of the emission comes out of fiber coating. To prevent this effect it is necessary to avoid exceeding of fiber bending radius.

2) Fiber brake – in this case irreversible power decrease will be observed as well as a partial output of optical emission in the break point that may become a reason of optical fiber coating heat and even its dissolution.

FC connector is a standard for fiber optic connections.

Preparations to operation

1) Install copper radiator supplied together with a laser diode on flat and hard surface;

2) Apply a thin flat layer of heat sink paste (thermopaste) like KTP-8 (not included) on a radiator surface where the laser diode is going to be installed;

3) Fix the laser diode in HHL package on the radiator using M3 screws (included);

4) Install pumping driver close to the radiator;

5) Using included cable connect the driver with the laser diode in HHL package. Connect additional connectors HU-4 and WF-4 (4 pins) between each other. These connectors are for supply 12V power to coolling fan as well as for reading of values from thermoresistor built-into the radiator.

Package mounting and heat sink recommendations.

To guarantee effective laser diode and built-in Peltie thermocooller operation it is necessary to provide sufficient heat sink from the lower surface of HHL package. For this purpose HHL package must be mounted on a radiator using a heat sink paste (thermopaste) like KTP-8 (not included).

Laser module also includes a radiator of copper plates equipped with a fan for compulsory cooling.

To install HHL package onto the radiator surface it is necessary to use mounting holes of the package with M3 screws (included).

Non-compliance of above requirements may result in decrease of output optical power and failure of Peltie thermocooller.

Fiber optic operation recommendations.

Standard optical fiber allows bending radius up to 70-100mm, therefore to avoid its damage it is strictly prohibited to exceed above mentioned fiber bending radius during operation with the laser module, its transportation or storage!

In case of operation of the laser diode with fiber bend exceeding radius allowed following situations are possible:

1) Reversible decrease of optical power to do with failure of optical fiber waveguide behavior when due to strong bending part of the emission comes out of fiber coating. To prevent this effect it is necessary to avoid exceeding of fiber bending radius.

2) Fiber brake – in this case irreversible power decrease will be observed as well as a partial output of optical emission in the break point that may become a reason of optical fiber coating heat and even its dissolution.

FC connector is a standard for fiber optic connections.

Preparations to operation

1) Install copper radiator supplied together with a laser diode on flat and hard surface;

2) Apply a thin flat layer of heat sink paste (thermopaste) like KTP-8 (not included) on a radiator surface where the laser diode is going to be installed;

3) Fix the laser diode in HHL package on the radiator using M3 screws (included);

4) Install pumping driver close to the radiator;

5) Using included cable connect the driver with the laser diode in HHL package. Connect additional connectors HU-4 and WF-4 (4 pins) between each other. These connectors are for supply 12V power to coolling fan as well as for reading of values from thermoresistor built-into the radiator.

Operation order

Turn on the power of the laser diode module driver and start operation in accordance the driver operation manual.

Operation termination

After completion of operation turn off the pumping driver and disconnect the laser diode module if necessary.

Laser diode module kit

1) Laser diode in HHL package – 1 pc.;

2) Copper radiator with fan – 1 pc.;

3) М3 screws – 4 pcs;

4) Laser diode in HHL package technical passport – 1 pc.;

5) Quick Start Guide how to assemble the laser diode module and optical fiber operation rules.

Operation order

Turn on the power of the laser diode module driver and start operation in accordance the driver operation manual.

Operation termination

After completion of operation turn off the pumping driver and disconnect the laser diode module if necessary.

Laser diode module kit

1) Laser diode in HHL package – 1 pc.;

2) Copper radiator with fan – 1 pc.;

3) М3 screws – 4 pcs;

4) Laser diode in HHL package technical passport – 1 pc.;

5) Quick Start Guide how to assemble the laser diode module and optical fiber operation rules.

1-TEC (-)

2

3- NC

4-Laser Anode (+)

5-Thermistor (2)

6-Thermistor (1)

7-Laser Cathode (-)

8- NC

9- NC

10-TEC (+)

Pinouts assignment of the additional connector HU-4 (4 pins)

1-TEC (-)

2

3- NC

4-Laser Anode (+)

5-Thermistor (2)

6-Thermistor (1)

7-Laser Cathode (-)

8- NC

9- NC

10-TEC (+)

Pinouts assignment of the additional connector HU-4 (4 pins)

Package mounting and heat sink recommendations.

To guarantee effective laser diode and built-in Peltie thermocooller operation it is necessary to provide sufficient heat sink from the lower surface of HHL package. For this purpose HHL package must be mounted on a radiator using a heat sink paste (thermopaste) like KTP-8 (not included).

Laser module also includes a radiator of copper plates equipped with a fan for compulsory cooling.

To install HHL package onto the radiator surface it is necessary to use mounting holes of the package with M3 screws (included).

Non-compliance of above requirements may result in decrease of output optical power and failure of Peltie thermocooller.

Fiber optic operation recommendations.

Standard optical fiber allows bending radius up to 70-100mm, therefore to avoid its damage it is strictly prohibited to exceed above mentioned fiber bending radius during operation with the laser module, its transportation or storage!

In case of operation of the laser diode with fiber bend exceeding radius allowed following situations are possible:

1) Reversible decrease of optical power to do with failure of optical fiber waveguide behavior when due to strong bending part of the emission comes out of fiber coating. To prevent this effect it is necessary to avoid exceeding of fiber bending radius.

2) Fiber brake – in this case irreversible power decrease will be observed as well as a partial output of optical emission in the break point that may become a reason of optical fiber coating heat and even its dissolution.

FC connector is a standard for fiber optic connections.

Preparations to operation

1) Install copper radiator supplied together with a laser diode on flat and hard surface;

2) Apply a thin flat layer of heat sink paste (thermopaste) like KTP-8 (not included) on a radiator surface where the laser diode is going to be installed;

3) Fix the laser diode in HHL package on the radiator using M3 screws (included);

4) Install pumping driver close to the radiator;

5) Using included cable connect the driver with the laser diode in HHL package. Connect additional connectors HU-4 and WF-4 (4 pins) between each other. These connectors are for supply 12V power to coolling fan as well as for reading of values from thermoresistor built-into the radiator.

Package mounting and heat sink recommendations.

To guarantee effective laser diode and built-in Peltie thermocooller operation it is necessary to provide sufficient heat sink from the lower surface of HHL package. For this purpose HHL package must be mounted on a radiator using a heat sink paste (thermopaste) like KTP-8 (not included).

Laser module also includes a radiator of copper plates equipped with a fan for compulsory cooling.

To install HHL package onto the radiator surface it is necessary to use mounting holes of the package with M3 screws (included).

Non-compliance of above requirements may result in decrease of output optical power and failure of Peltie thermocooller.

Fiber optic operation recommendations.

Standard optical fiber allows bending radius up to 70-100mm, therefore to avoid its damage it is strictly prohibited to exceed above mentioned fiber bending radius during operation with the laser module, its transportation or storage!

In case of operation of the laser diode with fiber bend exceeding radius allowed following situations are possible:

1) Reversible decrease of optical power to do with failure of optical fiber waveguide behavior when due to strong bending part of the emission comes out of fiber coating. To prevent this effect it is necessary to avoid exceeding of fiber bending radius.

2) Fiber brake – in this case irreversible power decrease will be observed as well as a partial output of optical emission in the break point that may become a reason of optical fiber coating heat and even its dissolution.

FC connector is a standard for fiber optic connections.

Preparations to operation

1) Install copper radiator supplied together with a laser diode on flat and hard surface;

2) Apply a thin flat layer of heat sink paste (thermopaste) like KTP-8 (not included) on a radiator surface where the laser diode is going to be installed;

3) Fix the laser diode in HHL package on the radiator using M3 screws (included);

4) Install pumping driver close to the radiator;

5) Using included cable connect the driver with the laser diode in HHL package. Connect additional connectors HU-4 and WF-4 (4 pins) between each other. These connectors are for supply 12V power to coolling fan as well as for reading of values from thermoresistor built-into the radiator.

Operation order

Turn on the power of the laser diode module driver and start operation in accordance the driver operation manual.

Operation termination

After completion of operation turn off the pumping driver and disconnect the laser diode module if necessary.

Laser diode module kit

1) Laser diode in HHL package – 1 pc.;

2) Copper radiator with fan – 1 pc.;

3) М3 screws – 4 pcs;

4) Laser diode in HHL package technical passport – 1 pc.;

5) Quick Start Guide how to assemble the laser diode module and optical fiber operation rules.

Operation order

Turn on the power of the laser diode module driver and start operation in accordance the driver operation manual.

Operation termination

After completion of operation turn off the pumping driver and disconnect the laser diode module if necessary.

Laser diode module kit

1) Laser diode in HHL package – 1 pc.;

2) Copper radiator with fan – 1 pc.;

3) М3 screws – 4 pcs;

4) Laser diode in HHL package technical passport – 1 pc.;

5) Quick Start Guide how to assemble the laser diode module and optical fiber operation rules. We can ship to you both based on FCA Moscow or FCA Hong Kong as per your request

The warranty term on our products is 12 month.

Laser module consists of following parts:

1) Laser diode in HHL package;

2) Copper radiator with a cooling fan;

3) Connecting cable between the radiator and a pumping driver.

HHL package is a hermetically sealed package with 9 pins. The package contains:

laser diode, Peltie thermocooller, thermoresistor, laser emission input system into optical fiber and other laser design elements.

1-TEC (-)

2

3- NC

4-Laser Anode (+)

5-Thermistor (2)

6-Thermistor (1)

7-Laser Cathode (-)

8- NC

9- NC

10-TEC (+)

Pinouts assignment of the additional connector HU-4 (4 pins)

1-TEC (-)

2

3- NC

4-Laser Anode (+)

5-Thermistor (2)

6-Thermistor (1)

7-Laser Cathode (-)

8- NC

9- NC

10-TEC (+)

Pinouts assignment of the additional connector HU-4 (4 pins)

Package mounting and heat sink recommendations.

To guarantee effective laser diode and built-in Peltie thermocooller operation it is necessary to provide sufficient heat sink from the lower surface of HHL package. For this purpose HHL package must be mounted on a radiator using a heat sink paste (thermopaste) like KTP-8 (not included).

Laser module also includes a radiator of copper plates equipped with a fan for compulsory cooling.

To install HHL package onto the radiator surface it is necessary to use mounting holes of the package with M3 screws (included).

Non-compliance of above requirements may result in decrease of output optical power and failure of Peltie thermocooller.

Fiber optic operation recommendations.

Standard optical fiber allows bending radius up to 70-100mm, therefore to avoid its damage it is strictly prohibited to exceed above mentioned fiber bending radius during operation with the laser module, its transportation or storage!

In case of operation of the laser diode with fiber bend exceeding radius allowed following situations are possible:

1) Reversible decrease of optical power to do with failure of optical fiber waveguide behavior when due to strong bending part of the emission comes out of fiber coating. To prevent this effect it is necessary to avoid exceeding of fiber bending radius.

2) Fiber brake – in this case irreversible power decrease will be observed as well as a partial output of optical emission in the break point that may become a reason of optical fiber coating heat and even its dissolution.

FC connector is a standard for fiber optic connections.

Preparations to operation

1) Install copper radiator supplied together with a laser diode on flat and hard surface;

2) Apply a thin flat layer of heat sink paste (thermopaste) like KTP-8 (not included) on a radiator surface where the laser diode is going to be installed;

3) Fix the laser diode in HHL package on the radiator using M3 screws (included);

4) Install pumping driver close to the radiator;

5) Using included cable connect the driver with the laser diode in HHL package. Connect additional connectors HU-4 and WF-4 (4 pins) between each other. These connectors are for supply 12V power to coolling fan as well as for reading of values from thermoresistor built-into the radiator.

Package mounting and heat sink recommendations.

To guarantee effective laser diode and built-in Peltie thermocooller operation it is necessary to provide sufficient heat sink from the lower surface of HHL package. For this purpose HHL package must be mounted on a radiator using a heat sink paste (thermopaste) like KTP-8 (not included).

Laser module also includes a radiator of copper plates equipped with a fan for compulsory cooling.

To install HHL package onto the radiator surface it is necessary to use mounting holes of the package with M3 screws (included).

Non-compliance of above requirements may result in decrease of output optical power and failure of Peltie thermocooller.

Fiber optic operation recommendations.

Standard optical fiber allows bending radius up to 70-100mm, therefore to avoid its damage it is strictly prohibited to exceed above mentioned fiber bending radius during operation with the laser module, its transportation or storage!

In case of operation of the laser diode with fiber bend exceeding radius allowed following situations are possible:

1) Reversible decrease of optical power to do with failure of optical fiber waveguide behavior when due to strong bending part of the emission comes out of fiber coating. To prevent this effect it is necessary to avoid exceeding of fiber bending radius.

2) Fiber brake – in this case irreversible power decrease will be observed as well as a partial output of optical emission in the break point that may become a reason of optical fiber coating heat and even its dissolution.

FC connector is a standard for fiber optic connections.

Preparations to operation

1) Install copper radiator supplied together with a laser diode on flat and hard surface;

2) Apply a thin flat layer of heat sink paste (thermopaste) like KTP-8 (not included) on a radiator surface where the laser diode is going to be installed;

3) Fix the laser diode in HHL package on the radiator using M3 screws (included);

4) Install pumping driver close to the radiator;

5) Using included cable connect the driver with the laser diode in HHL package. Connect additional connectors HU-4 and WF-4 (4 pins) between each other. These connectors are for supply 12V power to coolling fan as well as for reading of values from thermoresistor built-into the radiator.

Operation order

Turn on the power of the laser diode module driver and start operation in accordance the driver operation manual.

Operation termination

After completion of operation turn off the pumping driver and disconnect the laser diode module if necessary.

Laser diode module kit

1) Laser diode in HHL package – 1 pc.;

2) Copper radiator with fan – 1 pc.;

3) М3 screws – 4 pcs;

4) Laser diode in HHL package technical passport – 1 pc.;

5) Quick Start Guide how to assemble the laser diode module and optical fiber operation rules.

Operation order

Turn on the power of the laser diode module driver and start operation in accordance the driver operation manual.

Operation termination

After completion of operation turn off the pumping driver and disconnect the laser diode module if necessary.

Laser diode module kit

1) Laser diode in HHL package – 1 pc.;

2) Copper radiator with fan – 1 pc.;

3) М3 screws – 4 pcs;

4) Laser diode in HHL package technical passport – 1 pc.;

5) Quick Start Guide how to assemble the laser diode module and optical fiber operation rules.

1-TEC (-)

2

3- NC

4-Laser Anode (+)

5-Thermistor (2)

6-Thermistor (1)

7-Laser Cathode (-)

8- NC

9- NC

10-TEC (+)

Pinouts assignment of the additional connector HU-4 (4 pins)

1-TEC (-)

2

3- NC

4-Laser Anode (+)

5-Thermistor (2)

6-Thermistor (1)

7-Laser Cathode (-)

8- NC

9- NC

10-TEC (+)

Pinouts assignment of the additional connector HU-4 (4 pins)

Package mounting and heat sink recommendations.

To guarantee effective laser diode and built-in Peltie thermocooller operation it is necessary to provide sufficient heat sink from the lower surface of HHL package. For this purpose HHL package must be mounted on a radiator using a heat sink paste (thermopaste) like KTP-8 (not included).

Laser module also includes a radiator of copper plates equipped with a fan for compulsory cooling.

To install HHL package onto the radiator surface it is necessary to use mounting holes of the package with M3 screws (included).

Non-compliance of above requirements may result in decrease of output optical power and failure of Peltie thermocooller.

Fiber optic operation recommendations.

Standard optical fiber allows bending radius up to 70-100mm, therefore to avoid its damage it is strictly prohibited to exceed above mentioned fiber bending radius during operation with the laser module, its transportation or storage!

In case of operation of the laser diode with fiber bend exceeding radius allowed following situations are possible:

1) Reversible decrease of optical power to do with failure of optical fiber waveguide behavior when due to strong bending part of the emission comes out of fiber coating. To prevent this effect it is necessary to avoid exceeding of fiber bending radius.

2) Fiber brake – in this case irreversible power decrease will be observed as well as a partial output of optical emission in the break point that may become a reason of optical fiber coating heat and even its dissolution.

FC connector is a standard for fiber optic connections.

Preparations to operation

1) Install copper radiator supplied together with a laser diode on flat and hard surface;

2) Apply a thin flat layer of heat sink paste (thermopaste) like KTP-8 (not included) on a radiator surface where the laser diode is going to be installed;

3) Fix the laser diode in HHL package on the radiator using M3 screws (included);

4) Install pumping driver close to the radiator;

5) Using included cable connect the driver with the laser diode in HHL package. Connect additional connectors HU-4 and WF-4 (4 pins) between each other. These connectors are for supply 12V power to coolling fan as well as for reading of values from thermoresistor built-into the radiator.

Package mounting and heat sink recommendations.

To guarantee effective laser diode and built-in Peltie thermocooller operation it is necessary to provide sufficient heat sink from the lower surface of HHL package. For this purpose HHL package must be mounted on a radiator using a heat sink paste (thermopaste) like KTP-8 (not included).

Laser module also includes a radiator of copper plates equipped with a fan for compulsory cooling.

To install HHL package onto the radiator surface it is necessary to use mounting holes of the package with M3 screws (included).

Non-compliance of above requirements may result in decrease of output optical power and failure of Peltie thermocooller.

Fiber optic operation recommendations.

Standard optical fiber allows bending radius up to 70-100mm, therefore to avoid its damage it is strictly prohibited to exceed above mentioned fiber bending radius during operation with the laser module, its transportation or storage!

In case of operation of the laser diode with fiber bend exceeding radius allowed following situations are possible:

1) Reversible decrease of optical power to do with failure of optical fiber waveguide behavior when due to strong bending part of the emission comes out of fiber coating. To prevent this effect it is necessary to avoid exceeding of fiber bending radius.

2) Fiber brake – in this case irreversible power decrease will be observed as well as a partial output of optical emission in the break point that may become a reason of optical fiber coating heat and even its dissolution.

FC connector is a standard for fiber optic connections.

Preparations to operation

1) Install copper radiator supplied together with a laser diode on flat and hard surface;

2) Apply a thin flat layer of heat sink paste (thermopaste) like KTP-8 (not included) on a radiator surface where the laser diode is going to be installed;

3) Fix the laser diode in HHL package on the radiator using M3 screws (included);

4) Install pumping driver close to the radiator;

5) Using included cable connect the driver with the laser diode in HHL package. Connect additional connectors HU-4 and WF-4 (4 pins) between each other. These connectors are for supply 12V power to coolling fan as well as for reading of values from thermoresistor built-into the radiator.

Operation order

Turn on the power of the laser diode module driver and start operation in accordance the driver operation manual.

Operation termination

After completion of operation turn off the pumping driver and disconnect the laser diode module if necessary.

Laser diode module kit

1) Laser diode in HHL package – 1 pc.;

2) Copper radiator with fan – 1 pc.;

3) М3 screws – 4 pcs;

4) Laser diode in HHL package technical passport – 1 pc.;

5) Quick Start Guide how to assemble the laser diode module and optical fiber operation rules.

Operation order

Turn on the power of the laser diode module driver and start operation in accordance the driver operation manual.

Operation termination

After completion of operation turn off the pumping driver and disconnect the laser diode module if necessary.

Laser diode module kit

1) Laser diode in HHL package – 1 pc.;

2) Copper radiator with fan – 1 pc.;

3) М3 screws – 4 pcs;

4) Laser diode in HHL package technical passport – 1 pc.;

5) Quick Start Guide how to assemble the laser diode module and optical fiber operation rules. We can ship to you both based on FCA Moscow or FCA Hong Kong as per your request

The warranty term on our products is 12 month.

COLLIMATING TUBE

1,00 $

FB-LD-ADP-TO9

45,00 $

FB-LD-RAD-HHL

130,00 $

FB-LD-DRV-15A

4900,00 $

FB-M1550-500TO3

370,00 $

FB-M1060-5000HO

1127,00 $

Do you have any questions?

Fill out the application and we will call you back within 5 minutes